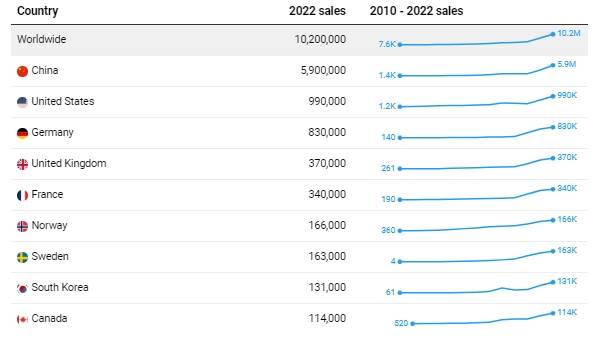

In 2022, electric vehicles (EVs) accounted for 15% of global car sales, with over 50% of these sales occurring in China.

The global sales of EVs have experienced a remarkable three-fold increase in the past three years. In 2020, approximately three million new electric cars were sold worldwide, while this number surged to an impressive 10 million in the following year.

In 2022, the global automotive market witnessed a significant shift towards electric vehicles, with every 20 new cars sold around the world, three of them being electric. This highlights the growing popularity and adoption of electric vehicles as a sustainable transportation choice.

The rapid growth in the adoption of electric cars can be attributed to the implementation of government policies and the enforcement of stricter emissions standards. According to the International Energy Agency (IEA), it is projected that by the end of 2023, approximately 14 million electric cars will be sold, reflecting a significant 35 percent increase compared to the previous year. This demonstrates the continued momentum and positive trajectory of the electric car market.

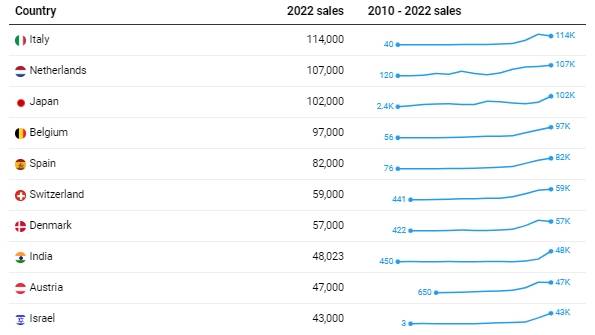

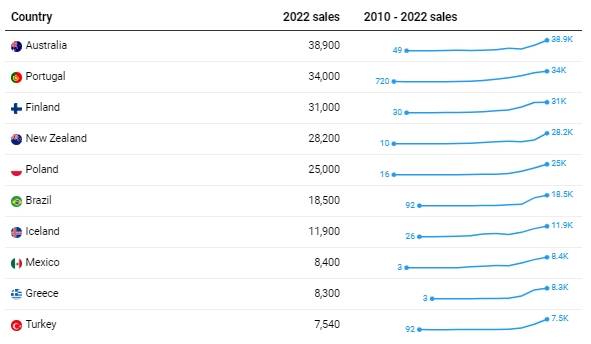

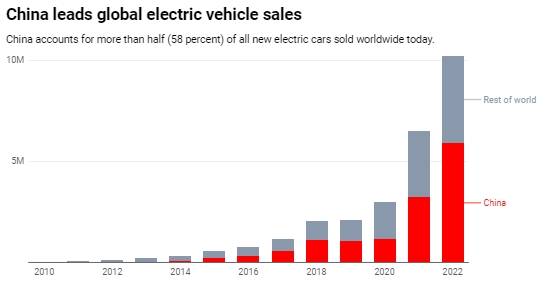

The provided data by the IEA allows us to analyze electric vehicle sales and trends across various countries from 2010 to 2022.

China Takes the Lead in Global Electric Vehicle Sales

China continues to solidify its position as a leader in the EV market, accounting for a remarkable 58 percent of all new electric cars sold globally. The IEA reports that in 2022 alone, China saw a staggering 5.9 million new EV sales, marking an impressive 80 percent increase compared to the previous year.

The China Association of Automobile Manufacturers even suggests that the actual sales figures reached a staggering seven million vehicles. The significant growth in China’s EV market underscores the country’s commitment to sustainable transportation and its rapid progress in embracing electric mobility.

Renowned Chinese automakers like BYD (Build Your Dreams) and SAIC-GM-Wuling have positioned themselves as key players in the EV market by prioritizing the production of affordable and highly efficient electric cars. Their commitment to innovation and sustainability has catapulted them into the ranks of major automobile producers and exporters on a global scale. With a strong emphasis on electric mobility, these Chinese manufacturers have successfully capitalized on the growing demand for EVs, contributing to the expansion of the electric car industry both within China and beyond.

As the largest car market globally, China’s significant growth in electric car sales is anticipated to play a crucial role in reducing the country’s carbon dioxide emissions, which currently rank as the highest in the world. The transition towards electric vehicles offers a promising solution to combatting climate change and promoting sustainable transportation in China, contributing to the overall global efforts to mitigate greenhouse gas emissions.

In China, electric cars account for a significant proportion of total car sales, with nearly one in three new cars (29 percent) being electric. This percentage surpasses that of Europe, where electric cars represent 21 percent of new car sales. In comparison, the United States stands at 8 percent, while the rest of the world hovers around 2 percent. These figures highlight China’s leading position in the adoption of electric vehicles and its commitment to transitioning to a more sustainable transportation landscape.

Understanding the Inner Workings of Electric Vehicles

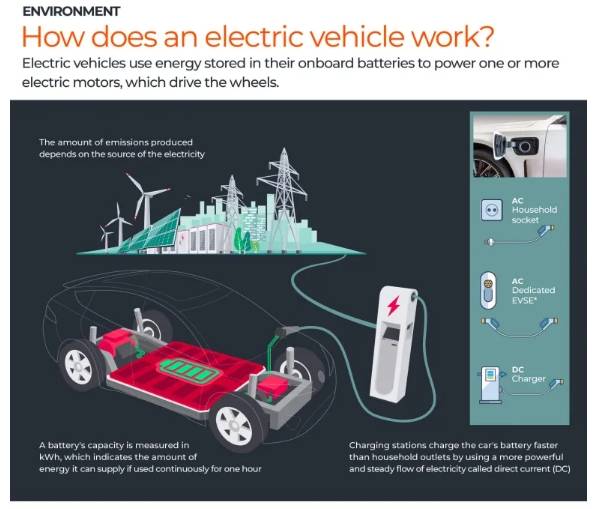

Electric vehicles rely on the energy stored in their onboard batteries to operate electric motors, which in turn propel the wheels of the vehicle.

The battery of an electric vehicle can be recharged by connecting the vehicle to a charging station or an electrical outlet using a designated connector. The capacity of a battery is typically measured in kilowatt-hours (kWh), which indicates the amount of energy it can provide if used continuously for one hour.

Charging stations utilize direct current (DC) to deliver a consistent and higher-powered flow of electricity, allowing for faster charging of the car’s battery compared to the standard alternating current (AC) outlets typically found in households.

EVs generate zero emissions during operation. However, the overall emissions associated with EVs can vary depending on the source of electricity used for charging. Renewable energy sources like wind or solar power produce minimal emissions, while sources like coal, gas, and oil tend to have higher emissions.

Key minerals used in EVs

Lithium-ion batteries, known for their lightweight and high energy density, are commonly used in the majority of plug-in hybrids and fully-electric vehicles. These batteries serve as the core component of electric vehicles, providing the necessary power for their operation.

In comparison to conventional cars, the production of EVs necessitates a considerably larger amount of minerals. To exemplify this disparity, the IEA states that, apart from steel and aluminum, the manufacturing of an electric car equipped with a single 75kWh NMC (nickel-manganese-cobalt) battery requires over 200kg (440 pounds) of minerals. In contrast, a traditional car of similar specifications would require approximately 34kg (75 pounds) of minerals for production.

Aside from common elements like copper and manganese found in both traditional and electric vehicles, the production of electric vehicles requires substantial amounts of graphite, nickel, cobalt, lithium, and rare earth minerals. Unfortunately, the extraction of these minerals in the Global South is often associated with environmental contamination and exploitation of workers, raising concerns about the sustainability and ethical implications of the electric vehicle supply chain.